Time is one of the most valuable resources we have, and not something that’s easily given up. When it comes to developing technology for medical use, loss of time means more than just products being late to a fast-paced market, it means lives are at stake.

The capabilities and of doctors and nurses have been growing exponentially since the Internet of Things has been integrated into the medical industry. Their response times are becoming shorter, and the data that health care practitioners need to perform their jobs is becoming more readily available.

The capabilities and of doctors and nurses have been growing exponentially since the Internet of Things has been integrated into the medical industry. Their response times are becoming shorter, and the data that health care practitioners need to perform their jobs is becoming more readily available.

It’s all thanks to efficient communication between a handful, a few dozen, or even thousands of devices.

Many of our clients have found success in the medical field. From the highest level of software development to custom hardware engineering, DornerWorks has provided the following solutions to some of the fastest growing health care organizations:

Some of the work we’ve done is helping medical facilities treat serious cases of hyper- and hypothermia, while others are being used to combat chronic back pain, stimulate bone growth, and even reconstruct damage CT scan data.

Here are several more ways DornerWorks has helped clients in the medical space provide life-saving services to their patients:

1. Ultrasonic Treatment Device software

1. Ultrasonic Treatment Device softwareLeveraging a new full-color LCD display with graphical user interface, encrypted USB communications, and a rechargeable battery, the system DornerWorks designed for a major medical device manufacturer is currently providing invaluable assistance as a bone healing stimulator.

2. MultiGen™ Radiofrequency Generator

2. MultiGen™ Radiofrequency GeneratorOur client developed the industry’s first and only radio frequency generator for chronic back pain able to treat up to 4 lesions simultaneously, with independent control. DornerWorks helped improve the ease of use by implementing a full-touch screen interface, the first such interface in a device of this kind.

3. Pneumatic Hospital Bed Controller

3. Pneumatic Hospital Bed ControllerA medical client gained a greater capacity to comfort and care for its patients through its air-filled hospital mattress, with pneumatic control technology designed, developed, and tested by DornerWorks.

Embedded technology in the finished product adjusts the air pressure in the support surface based on the characteristics of each patient.

4. Patient Hyper/Hypothermia Control system

4. Patient Hyper/Hypothermia Control systemWhen a patient arrives at the hospital with hyper- or hypothermia, seconds count. The wrong treatment could lend itself to disabling results, or even death.

The Patient Hyper/Hypothermia Control System software developed by DornerWorks provides the user interface for a medical device used for the prevention or treatment of hyper- and hypothermia by means of circulating temperature controlled water through blankets, pads, or wraps applied to the patient. According to embedded engineer Bruce Wehr, who worked on the project, “a another significant use is to lower a patient’s body temperature before surgery.”

The device simplifies, and automates the treatment process so medical professionals can concentrate on other areas of concern.

5. Blood Monitoring System software

5. Blood Monitoring System softwareAn innovative process to simulate blood parameters (Hct, Hgb and SO2) was developed by DornerWorks engineers for a device that uses optical sensors to monitor patient circulatory systems.

The device was enhanced with the capability to record I2C data traffic between the simulator and the device being tested, providing the client with greater accuracy in the final product.

6. USB Test Tool

6. USB Test ToolTechnicians are able to use the USB test tool DornerWorks developed to connect to failing products, determine what went wrong with their devices, and either implement the appropriate fix or send the information back to the engineers for quality improvement.

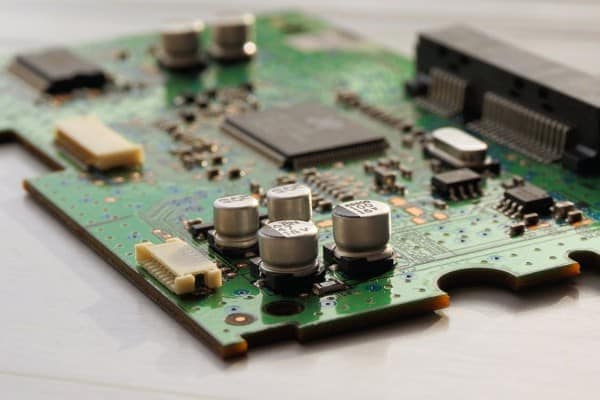

7. Obsolescence Redesign

7. Obsolescence RedesignA medical device company, faced with electronics hardware obsolescence on one of their significant product lines, came to DornerWorks to understand what it would take to update their hardware without having to redesign their software. The goal was to identify obsolete components and redesign the circuit card assembly in such a way that preserved the exact software loaded on those circuit cards, preventing the need to re-certify the software of the product for the medical marketplace.

Relying on DornerWorks expertise in hardware design, careful component selection, and manufacturing coordination with selected electronics contract manufacturers, the company was able to see those hardware updates delivered successfully, without having to face gaps in operation.

8. CAN to Ethernet/Wi-Fi Bridge SBC

8. CAN to Ethernet/Wi-Fi Bridge SBCFor a hospital bed bay identification application, DornerWorks developed a Single Board Computer as well as the software platform to operate the system that allows for a limitless number of the client’s microcontrollers and devices on a network to be accessible via Ethernet and Wi-Fi.

Medical histories contain vital information that health care practitioners depend on. When documents like CT scan data are damaged or corrupted, it becomes harder for those practitioners to make the best decisions.

DornerWorks engineers have developed a method of restoring CT scan files that have been damaged and cannot physically be opened. By reconstructing the information and filtering non-essential image data, we were able to provide a reliable solution to a frustrating problem many hospitals face.

DornerWorks engineers have developed a method of restoring CT scan files that have been damaged and cannot physically be opened. By reconstructing the information and filtering non-essential image data, we were able to provide a reliable solution to a frustrating problem many hospitals face.

Technology ages, and more efficient systems are bound to come along offering greater efficiency and capabilities. The medical field is not immune to this march of progress, and health care systems, especially, need to be prepared by upgrading their technology on a regular basis.

Engineering services provided by DornerWorks have allowed clients to adapt to new industry standards without a disruption in operation, increase their efficiency, and provide patients with better care.

Whether board design through ISO 60601 compliance, or software requirements through verification and validation, DornerWorks has the expertise to help clients in the medical field develop the technologies critical to their work, allowing them to get back to what they do best.

For more on the services DornerWorks has been providing to clients in the medical space, follow this link, or contact us directly.